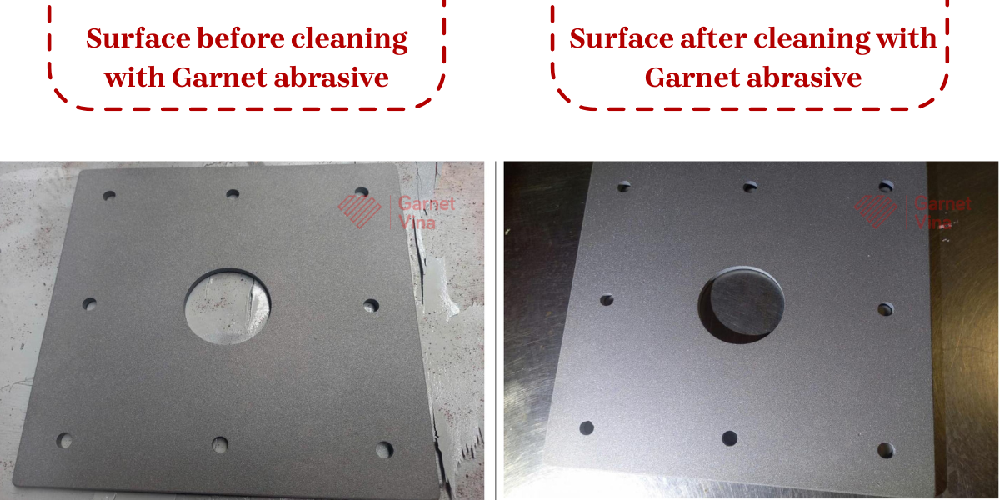

The difference between cleaned and uncleaned surfaces

In industrial metal surface preparation, there’s one critical step that’s often overlooked — proper cleaning. Whether the surface is properly prepared or not has a direct impact on paint adhesion, corrosion resistance, and the lifespan of the entire structure. At first glance, steel plates may appear the same, but in reality, the difference between a cleaned and uncleaned surface is substantial — in both performance and long-term cost.

Image: Surface before and after Garnet abrasive blasting

Uncleaned Surface – A Hidden Threat Beneath the Coating

After manufacturing or use, metal surfaces typically contain rust, grease, industrial dust, and oxidation layers. Without proper surface treatment, even high-end coatings can’t adhere firmly or last long. Within just a few months, you may see blistering, peeling, moisture intrusion, and spreading corrosion. That’s why many businesses face frequent repainting cycles or high maintenance costs.

Cleaned Surface – A Solid Foundation for All Coatings

In contrast, abrasive blasting with Garnet sand effectively removes rust, old paint, and contaminants — while simultaneously creating a standardized roughness profile that allows paint to grip tightly and evenly. These surfaces are often rated to international standards like SA 2.5 or SSPC - SP10, which are mandatory in industries such as oil & gas, shipbuilding, pressure vessels, and outdoor steel structures.

Why Choose Garnet Abrasive – A Cost-Effective & Efficient Solution

Not all blasting media deliver the same cleaning performance. Garnet abrasive, also known as natural garnet mineral, is highly regarded for its ability to:

- Deliver uniform surface roughness

- Rapidly remove rust and old coatings

- Generate minimal dust - safer for both workers and the environment

- Be reused 2 to 5 times, reducing material costs

- Contain no free silica, ensuring worker health and safety

Garnet is the ideal abrasive for achieving SA 2.5 or SA 3.0 profiles, fully aligned with SSPC/NACE international standards.

Real Comparison: Cleaned vs. Uncleaned Surfaces

An uncleaned surface often contains embedded contaminants, causing the coating to detach after a short period. In contrast, a surface cleaned with Garnet allows the paint to adhere firmly, ensures an even finish, improves corrosion resistance, and significantly reduces the likelihood of rework.

| Factor | Uncleaned Surface | Cleaned with Garnet |

| Paint adhesion | Weak, prone to peeling | Strong, uniform color |

| Corrosion resistance | Poor | High, long-lasting |

| Maintenance cost | Increases over time | Significantly reduced |

| Technical standard compliance | Not compliant | Meets SA 2.5 / SSPC-SP10 standards |

Surface cleaning is not just a technical procedure - it’s a decisive factor in the quality, appearance, and durability of your entire project. By using Garnet abrasive correctly - with the right mesh size, air pressure, and blasting process - you can achieve industry - standard surfaces while optimizing investment and long - term performance.

Tiếng Việt

Tiếng Việt  English

English